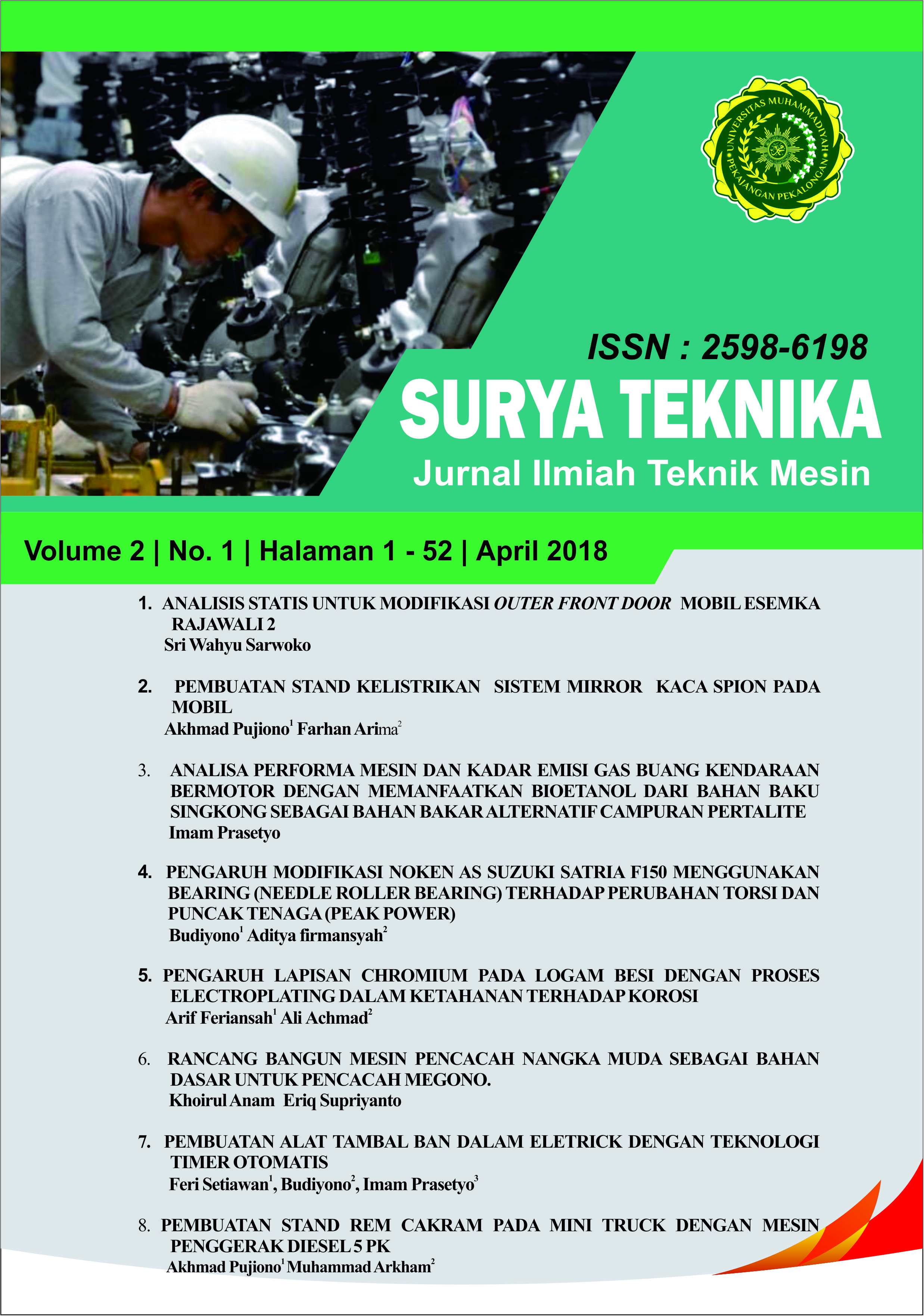

RANCANG BANGUN MESIN PENCACAH NANGKA MUDA SEBAGAI BAHAN DASAR UNTUK MEMBUAT MEGONO

DOI:

https://doi.org/10.48144/suryateknika.v2i1.1265Abstract

ABSTRACT

This plan aims to (1) resulted in the design and construction working drawings thrasher young jackfruit strong, sturdy, safe, and efficient. (2) Getting the results of a performance test Counting Machines young jackfruit better. (3) Getting the calculation analysis Counting Machines Nangka Muda. Three formulation of the problem posed and the third related to planning purposes. The process of designing thrasher young jackfruit is conducted in stages, namely planning and calculation. Analysis techniques include the analysis of power, torque occurring on the shaft and frame construction. Propulsion thrasher young jackfruit is planned to use two electric motors that are tailored to the ability of the electrical power for SMEs which is estimated to average about 900 to 1300 watts. The results of the design produces thrasher young jackfruit with the specifications of length 460 mm, width 360 mm and height 460 mm weight 25 kg. The production capacity thrasher young jackfruit 12 kg / hour. Source of propulsion engine is air-power electric motor of 120 watts and 135 watts with a round of 7500 rpm and 1400 rpm. The power transfer system using a V-belt with a shaft diameter of 12 mm. Frame construction made of angled profiles 30x30mmx2 mm with material St 42 and casing using eyser plate with a thickness of 0.8 mm. Cost is issued to make thrasher young jackfruit is Rp 803,000.

Indications of damage that can happen to a thrasher, among others: (1) The chopper blades were in direct contact with the workpiece to be blunt it is necessary to re-sharpening. (2) bearings are subjected to loads on the shaft rotation can occur hilarity. (3) electric motor which imposed exceeds the ability to work, will experience the heat, (4) the belt is experiencing gravity and friction will be loosened and wear.

Keywords: Power Analysis, Production Capacity, Construction Frame, Economic Efficiency